Corrective Action: prevent overheating, please refer to the limitations of the sensor as outlined in the specification sheet originally sent with the sensor when new. A proper heatsink as well as taking care not to exceed the temperature limit of the disc will prevent this type of damage from occurring.

Explanation: This is the number one cause of disc replacement with our sensors. Each coating type offered by Ophir-Spiricon has a specific power and energy damage threshold for localized power and energy shots incident on the surface of the absorber. The specification sheet for each sensor will specify the general limit for power and energy damage. The following formulas are used to determine the power and energy density of your laser beam respectively:

- CW lasers:

- [formula 1] Power Density = [ power (W) / ( 0.785 * diameter² ) ]

- [formula 2] Power Density = [ ( energy per pulse (J) * rep. Rate (Hz)) / ( 0.785 * diameter² ) ]

- Pulsed lasers:

- [formula 3] Energy Density = [ ( energy per pulse (J) ) / ( 0.785 * diameter² ) ]

These formulas have a few assumptions that may not always be the case. The first assumption is that the laser beam profile is a homogenous one i.e. flat top profile. This is not the case for all lasers. Many lasers have a Gaussian profile, while others have spikes or other abnormalities in the profile. These spikes can often have many factors of power and energy density greater than the beam has on average, resulting in small burn marks and localized overheating of the coating. Ophir-Spiricon has a wide range of beam profiling devices available if you would like to determine the profile of your laser.

Another subtle but extremely important thing to keep in mind is that pulsed lasers, particularly those with short pulse lengths (< ~500 us) have extremely high instantaneous energy densities. For example, although the laser might be pulsing at 5 Hz, if the pulse length is only 10 ns, all of the power is being delivered in an extremely short time. For a 10 watt average power pulsed laser at 5 Hz with a 10 ns pulse length, this would imply that the instantaneous energy density during each pulse is:

(2 watts / 10 ns ) = 2*108 W/s = 200,000 kW/s

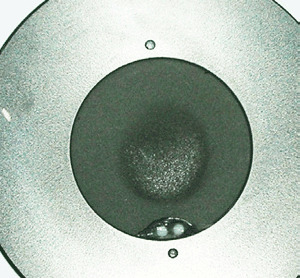

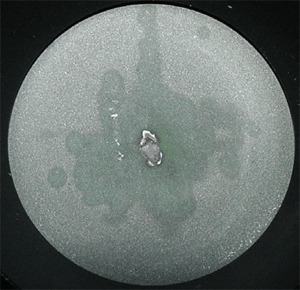

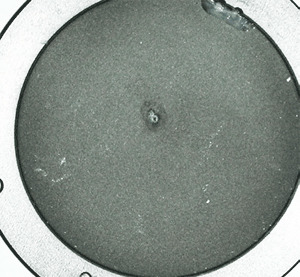

his is a theoretical example, and demonstrates the extreme damage capabilities of pulsed lasers. Many users occasionally get away with this type of use as the sensor is exposed to the instantaneous energy density for such a short period of time that the coating is literally being disintegrated in microscopic layers at a time. Due to the subtle nature of this type of damage, many times the user will not notice it occurring until after a significant number of pulses. This form of damage results in the largest number of sensor replacements. Please refer to Figures 4 through 11.

Ultra-High Velocity

Ultra-High Velocity