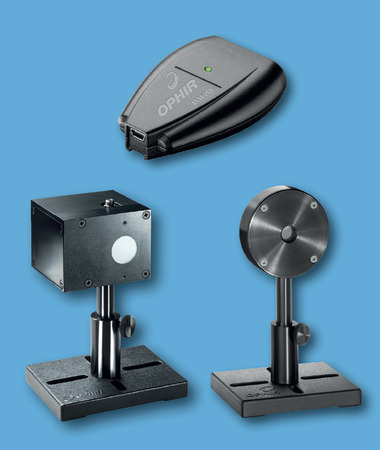

While the large 20mm aperture permits greater working distances, the inner diameter of the sphere is only 38mm, which enables a reaction time of just 2.8ns. Furthermore, a precision photodiode delivers calibrated power measurements, and a fast photodiode reproduces the pulse shape for display on the oscilloscope. In addition, the laser power is recorded with the Ophir 3A-FS thermal sensor in combination with the Ophir Juno external USB interface. For the laserfabrik team, a significant advantage of the two measurement systems was that the resultant data could be evaluated directly on the PC using the Ophir Starlab software.

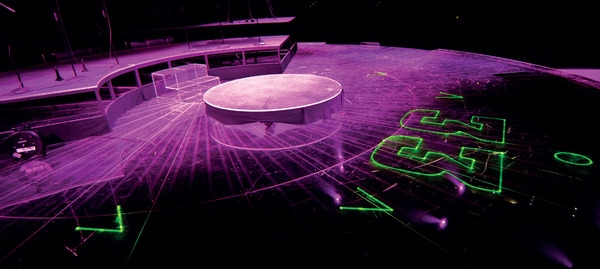

The measurements had to represent the on-stage situation as realistically as possible and, at the same time, be easy to carry out. In a hall, the diode laser was set up at a distance of 10 meters from the wall. The measurements were taken at 7.3m, or right at the leading edge of the audience area. As a basis for the experiments, Lucas Hamacher developed four practical projections of varying complexity, including, for example, denoting the amperage of electrical power on the ground or adding markings at the corners of the stage area.

The laser beam used for the stage marking traces out the selected projection. For this purpose, two mirrors are used to quickly change the position of the beam in the x- and y-directions so that — due to the slowness of the human eye — the complete symbol is perceived. Every pulse of the laser beam that hits the viewer's retina must be taken into account. In order to simulate the human eye, a diaphragm of 7mm is prescribed for the measurements for determining the MPE. However, since at 7.3m the laser beam has already expanded somewhat, in the experiments Lucas Hamacher used the integrating sphere with the Ophir 1.5-VIS-FPD-800 photodiode; the device contains the appropriate optics and provides a sufficiently large aperture. Laser power was measured using both the photodiode and an Ophir 3A-FS thermal sensor.

The measurements showed that the shape of the projection exerts significant influence on the power. In the projection of a triangle, the pulse duration measured on its edges was only 1/17 of what was measured at its vertices. Due to the inertia of the mirrors, changing the direction of the beam leads to a longer pulse duration and thus to a higher irradiation at these measuring points. In order to reliably adhere to the limit values, the dimming of the laser must be adapted individually to the projection. A general reduction in laser power makes no sense here, as this would come at the expense of the marking's visibility. These findings were operationalized for the application by comparing the limit value with the maximum measured power. The maximum power at a distance of 7.3m from the laser source was measured with both the Ophir photodiode and the Ophir 3A-FS sensor. Taking into account the respective wavelengths, in the next step, Lucas Hamacher determined the required attenuation (dimming) of the laser.

Since most commonly-used show lasers operate at higher powers, the attenuation required for stage marking is extreme. But in the case of very low powers, the adjustment must be exceedingly precise. In this case, the investigations revealed that 24-bit analog/digital converters should be used.

"Thanks to MKS' high-quality Ophir laser measurement devices we were able to accurately measure both the temporal characteristics per wavelength and the actual power of our projections."

Lucas Hamacher, Master Student Event Technology

Ultra-High Velocity

Ultra-High Velocity