Kevin Kirkham, Senior Manager, Product Development, Ophir-Spiricon, LLC

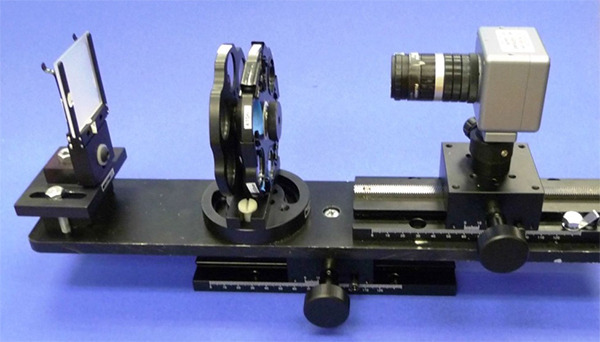

Laser beam profiling products are typically composed of a 2-dimensional sensor array, optical imaging and attenuation optics, and software that displays, analyzes, and records the visual representations of the distribution of light for measurement, archival, and retrieval. The heart of a laser beam profiling system is a scientific grade CCD or CMOS camera. The camera is selected and tested for linearity over the useable range of the system, uniform response, and accuracy. There are no blemishes or inoperative pixels in the sensor arrays that detect the scene and convert it to an electronic signal. The camera is selected for its wide dynamic range and typically has had the window and IR cut-off filter removed so that there are no interfering optics to distort the image or limit the spectral response. Beam profiling cameras typically provide images with signal to noise ratio of 58db or better and are digitized to 12 to 16 bits or more.

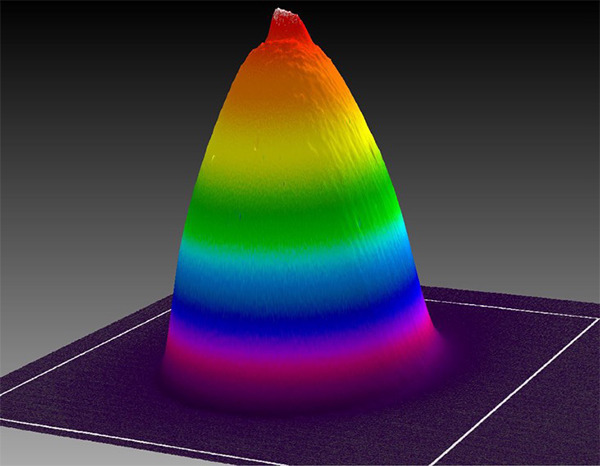

Laser beam profiling software, the brains of the product, provides user selectable images that intuitively describe the intensity distribution of the light source under test. False color, two-dimensional, and isometric three-dimensional displays inform the user of variations in the light intensity pattern emitted from the devices under test.

Because laser beam profiling systems are designed and manufactured to provide high fidelity images, it is easy to measure and document the performance of other light sources where the intensity distribution is critical to the application. Lightemitting devices ranging from LED and luminaries to dental curing lamps and sterilization systems may benefit. The list of applications is beyond the scope of this article but it can said these systems are capable of providing very useful information for the alignment and analysis of any light source whose intensity distribution pattern is critical to the efficacy of its application.

Measurement systems can be quickly and easily constructed to assist in manufacture, alignment, and documentation of such products. Commercial off-theshelf software provided with these products permits the user to make highresolution spatial measurements as a function of spot size and intensity distribution of light. With known spatial and intensity calibration, beam profiling systems can be employed to provide an accurate, traceable understanding of the distribution of light intensities from many commercial devices.

A useful example of the application of a laser beam profile (LBP) system employed to analyze non-laser light is the analysis of dental curing lamps. These monochromatic or multi-wavelength, handheld systems are used in dentists’ offices around the world to cure polymer resins for restorative dental procedures. UV and visible light cure compounds thus providing lifelike, color matching restorations. These realistic restorations are made possible by LED powered curing of these composites. Fully and uniformly cured and hardened restorations can now be quickly tailored thanks to new, light-polymerized resin compositions and high intensity, UV and blue light sources that feature evenly distributed or homogeneous light.

The distribution of light produced by these light sources can be quickly measured with the use of a modified laser beam profiling system. Non-laser optical metrology applications of the LBP products utilize a diffusive target and imaging lens. The target provides a flat, uniform surface which can impinge the light source under test. The target must be secured in the light path and is typically placed at the same plane or distance from the source where the light or illumination system will be employed.

Ultra-High Velocity

Ultra-High Velocity