Dick Rieley , Field Sales Engineer III, Mid-Atlantic Region, Ophir-Spiricon

This task puts a financial burden on the lab. They need to use commercially available tools in the most efficient manner possible, and get them funded through the same program under which the laser sources were acquired. Unfortunately, when it becomes known that this type of laser performance information is needed, the laser systems are typically already in place, the experiments are ready to be conducted, and any delays could be counterproductive to the guidelines of the grant. Therefore laser measurement equipment must be found that is cost effective, commercially available, easy to use, quick to set up, and informative to the level of full acceptance to scientific staff, as well as to the community reviewing the grant results.

In this application, the University had acquired three (3) different lasers, all low power, i.e., <5 mW. The challenge arose in that the wavelength of the laser sources spanned a large range. The first laser was a 700 nm source with about a 3 mm diameter beam. The second was a 1300 nm source with a beam diameter about 3 mm. The last laser was a 1800 nm source with a beam diameter of 0.8 mm.

The initial selection of beam diagnostic equipment by the researcher resulted in a very expensive approach, quite sufficient but expensive. The equipment involved the choice of two beam profile cameras, one for use on the 700 nm source and a second for use on the 1300 nm and 1800 nm sources. As is often the case in university research, the budgets was tight, especially after most of the funding had been exhausted on the procurement of the lasers. That meant little was left over for diagnostic test equipment.

The solution was the Ophir-Spiricon XC-130 InGaAs beam profiling camera (30 um x 30 um pixels, 320 x 256 array, 9.6 x 7.6 mm size). This camera could be used for all three laser applications, delivering easy of use, accurate results, and a common set of equipment. This particular diagnostic camera was selected based on a physical laboratory test of all three sources. Although the baseline specification for the Spiricon XC130 reports absorption sensitivity of the array from 900 to1700 nm, previous testing had shown that with sufficient power, the camera array can image below 900 nm, down to possibly 700 nm, and upwards to 1800 nm. However, the specification was firm and no guarantees were offered so testing was mandatory.

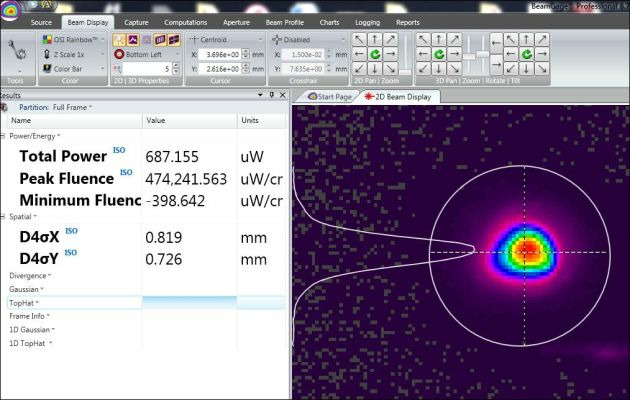

The first test was conducted on the 700 nm source, with power measured at 281 uW average power. The sensitivity of the XC130, using a feature of the software that allows the summing of 11 camera frames, provided sufficient imaging capability to view the beam and obtain accurate measurements. Although the camera is not specified for a shorter wavelength of 700 nm and 281 uW, the camera can be used to shorter wavelengths (no guarantees by the manufacturer ) and enhanced using the beam diagnostic software.

Ultra-High Velocity

Ultra-High Velocity