Whether you have a laser pointer operating at a few milliwatts, a laser being used for micro welding pulsing at a few Joules of energy per pulse, or a laser being used to disable drones with 10's or even 100's of kilowatts of continuous-wave power, the performance of that laser can be characterized by its Power Density (expressed as Watts per square centimeter – W/cm²).

Power Density is defined as the amount of laser light (expressed in Watts for average or continuous-wave power) with respect to the beam size at which the laser is doing its work (expressed in a unit of area such as cm²), commonly known as a "spot size." Too high a Power Density, due to a relatively higher laser power or relatively smaller spot size, will usually cause the laser to overwork or uncontrollably damage objects in its beam path that aren't meant to be damaged. Conversely, too low a Power Density, due to a relatively low laser power level or a relatively larger spot size, will cause the laser to not do any work at all. Understanding the laser's Power Density as it relates to the material being processed is vital to knowing how the overall system will perform.

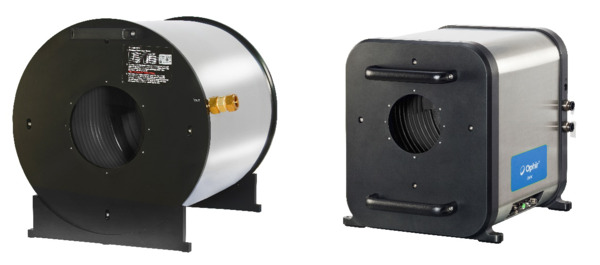

The top of the Power Density equation (W/cm²) represents the amount of laser light being applied. This is achieved by measuring the laser's average or continuous-wave power (or pulse energy for pulsed lasers). For Directed Energy lasers, this means 10's or even the 100's of kilowatts of power. While you may think that this is difficult to determine, there are devices that will measure laser powers that high. Conventional water-cooled thermopile sensors can measure from 1kW to 30kW of laser power with ±3% NIST-traceable accuracy. In addition, the 150K-W power measurement system mentioned earlier uses calorimeter measurements of differences in water temperature to measure laser average or continuous-wave power with ±5% NIST-traceable accuracy from 10kW to 150kW and beam sizes up to 200mm in diameter.

The bottom of the Power Density equation is a measurement of the laser's beam profile. Beam Profiling is a collection of laser characteristics that correlate to the laser's quality and usually consist of the size and shape of the laser beam, as well as the spatial or energy distribution across the beam. The quality of the laser can also be measured by its caustic measurements such as Rayleigh Length, M², Beam Parameter Product (BPP), K value, among others, which are an indication of the laser's ability to focus.

When a laser source is developed, the manufacturer includes one or more of these ratings in the product specifications to illustrate the quality of the laser being purchased. For example, an M² rating for a single mode Gaussian laser with a value of 1 would indicate the highest-quality laser possible.

Ultra-High Velocity

Ultra-High Velocity